SQM – Special Component Inspection

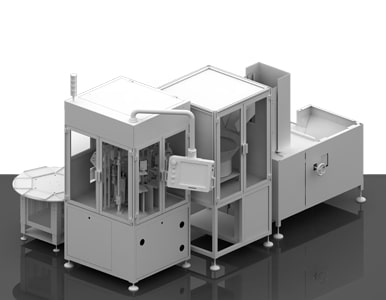

SQM is a step-by-step sorting machine for special applications. It is designed to perform multiple dimensional, quality, and mechanical functionality inspections on standard parts and special components.

- Optimal for dimensional, quality, and mechanical functionality inspections

- Suitable for special inspections and/or non-standard parts

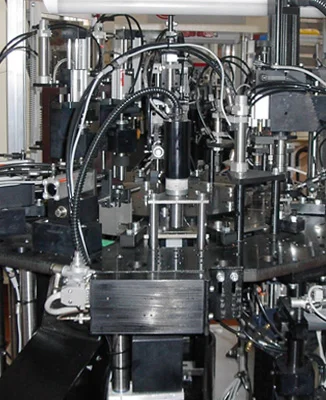

- Can be equipped with optical, mechanical, laser, 3D inspection stations, and assembly stations

Available inspection types

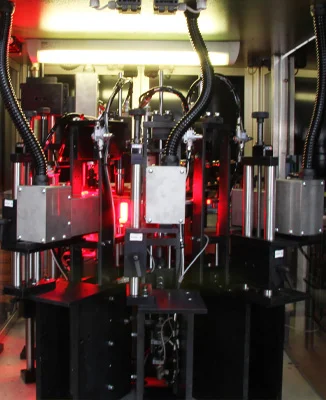

The SQM machine can be equipped for the following inspections:

- Dimensional and quality inspections with Bi-telecentric and Pericentric camera optics

- Dimensional inspections with Laser Control Unit

- Dimensional inspections with 3D Laser Unit

- Mechanical functionality inspections

- Assembly stations

Data sheet

| PARAMETRS | SQM |

|---|---|

| Dimensional ranges of the parts | |

| Diameters min/max | 5 – 50 mm |

| Lenght min/max | 10 – 180 mm |

| Control Units Available on the machine | |

| Optical inspection Units (num. max) | 6 |

| Laser 2D Control Unit | ✓ |

| Crack Control Unit with Eddy Currents (TTH) | ✓ |

| Mechanical Control Unit | ✓ |

| Assembly Unit | ✓ |

| Modal Analisys Control Unit | ✓ |

| Machine specifications | |

| Speed rates | 2000 -3000 pezzi/h |

| Dimensions | 1200 x 2200 mm |

| Wegiht | 1700kg |

Parts

The SQM machine is optimized to perform inspections on the following parts:

- Torsion bars

- Guide pins

- Pump pins

- Eccentric pins

- Screws

- Hinges

- Special shafts

- Shafts

- Dowels

- Nozzles

- Valves

- Engine valves

- Screws with washer

Request more informations

Champs offers turnkey solutions, long-term support, and consultancy to achieve the highest quality standards.

For more information about our machinery, please contact us.

Download

Download catalog in .pdf format

The data are subject to change without notice